Battery Thermal Runaway Detection with Posifa’s MEMS Hydrogen Sensor Technology

Hydrogen detection is well on its way to becoming the gold standard for triggering battery failure alarms in electric vehicle (EVs). This is because elevated levels of hydrogen are the earliest detectable indication that a thermal runaway condition is imminent. More obvious symptoms of a catastrophic thermal event—such as voltage drop, the appearance of smoke, temperature rise, pressure rise, and visible venting—come too late to serve as a warning that the driver needs to pull over and get out of the car. Off-gassing of hydrogen is detectable before any of these other warning signs and thus allows a battery safety alarm to be generated much earlier. This early warning capability is required by various safety agencies with respect to EVs; vehicle passengers need to be alerted at least five minutes before thermal runaway has progressed to the point where it could cause an explosion, smoke, or flame event.

Battery leakage detection sensors work by measuring H2 concentrations and communicating that information to the vehicle’s ECU. A module containing the sensor is placed in the battery enclosure, allowing it to sense the H2 gas generated during a failure mode. The sensor needs to be exposed in order to measure constantly the hydrogen concentration in the air surrounding the battery pack. Obviously, the sensor element needs to be as robust as possible to handle conditions in the automotive environment.

Sometimes pressure sensors are used to trigger battery failure alarms, but they’re slower and not as effective as hydrogen sensors at detecting the full range of modes in which an EV battery can fail. Hydrogen sensors react faster than pressure sensors to short circuit conditions (as shown by nail penetration testing) and battery cell overcharge. Hydrogen sensors can moreover detect cell re-overcharge conditions to which pressure sensors are non-reactive. In addition, there are many battery pack architectures where pressure sensors don’t work at all because their ventilation requirements make pressure increases undetectable.

Solutions for battery management system (BMS) hydrogen detection from Posifa Technologies are based on a MEMS hydrogen sensor that detects hydrogen concentrations in the air by measuring the change in thermal conductivity of the gas mixture inside the BMS compartment. This measurement approach provides better long-term stability, and enables a smaller form factor, than hydrogen sensors that are triggered by chemical reactions that eventually cause the sensor to degrade. Posifa’s technology also allows the hydrogen detection capability to be realized at a much lower cost thanks to the company’s highly repeatable, high-volume CMOS MEMS technology.

The actual sensor element is based on Posifa’s second-generation thermal conductivity die. The devices feature one die sealed in dry air and acting as a reference, while the other is exposed to the gas mixture. This design enables an excellent signal-to-noise ratio due to common-mode noise rejection and a maximization of the signal amplification. For safe operation, the sensor is excited with a pulsed waveform (400 ms on and 1,000 ms off) to minimize the heater temperature.

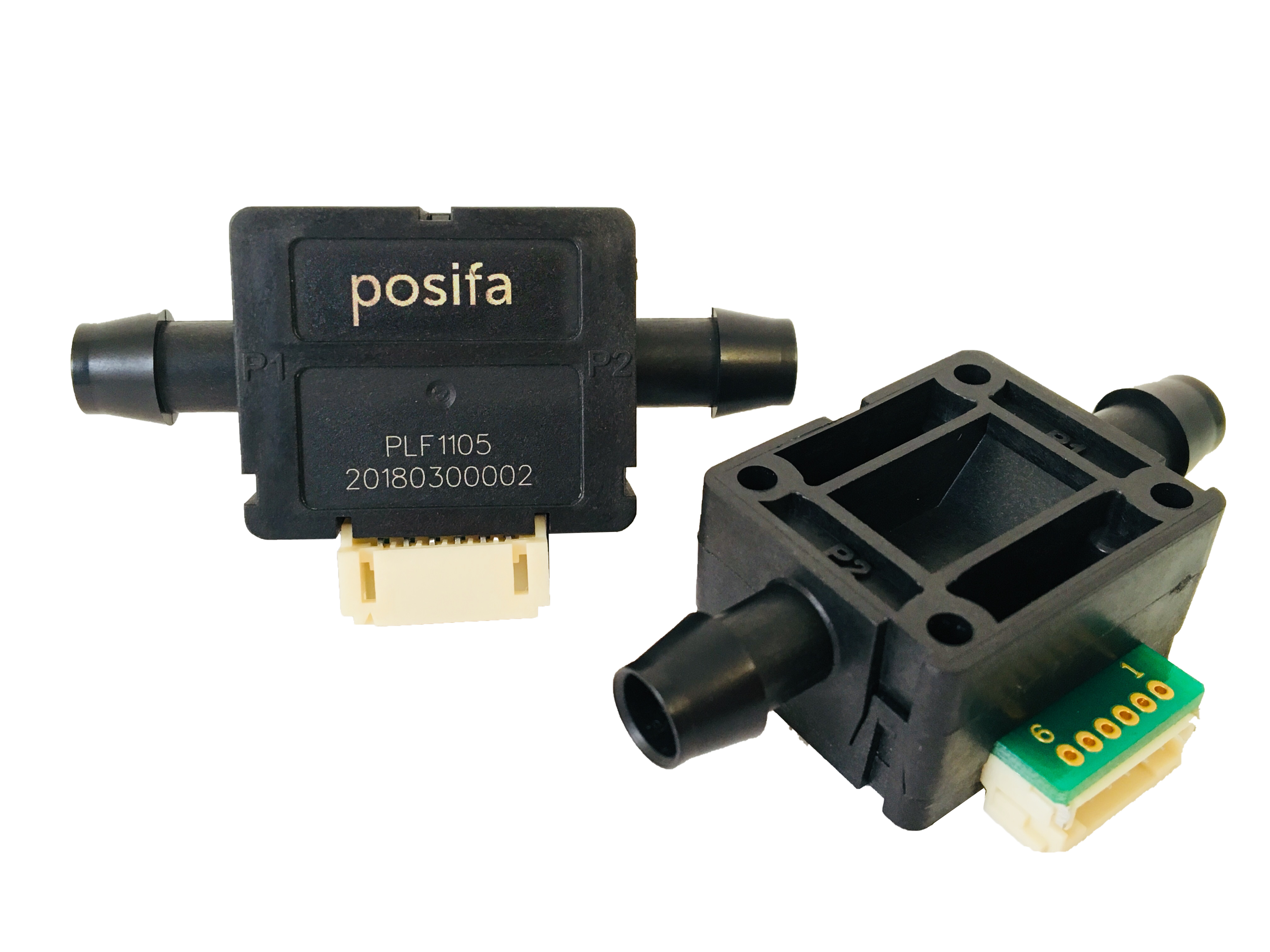

Because of the extremely small size of the sensor element and its straightforward principle of operation, Posifa’s hydrogen sensing technology can be offered in many different form factors and adapted to a very wide range of OEM requirements. Posifa Technologies has the manufacturing expertise and resources to deliver hydrogen sensing solutions at various levels of modular integration. Our technology can thus be integrated into any type of battery pack irrespective of ventilation technology, communication protocol, and so forth.

Key Features:

- The hydrogen sensors consist of two thermal conductivity dies in a differential configuration, packaged in a compact surface-mount form factor

- For increased long-term stability, the devices detect hydrogen concentrations in the air by measuring the change in thermal conductivity of the gas mixture

- Posifa’s highly repeatable, high-volume CMOS MEMS technology lowers costs

Key Specifications and Benefits:

- Excellent signal-to-noise ratio

- Broadest available ranges, up to 100 % volume

- Fast response time of < 1.4 s

- Typical long-term stability of 0.1 % F.S./year

- Typical repeatability of 0.05 % F.S.

- Operating temperature: -25 °C to +85 °C

- Pulsed excitation minimizes the heater temperature for safe operation